What is Ethanol?

Ethanol or ethyl alcohol (C2H5OH) is a biofuel that is naturally produced by fermentation of sugar. While it is primarily derived by extracting sugar from sugarcane, other organic sources like foodgrains can also be used for its production.

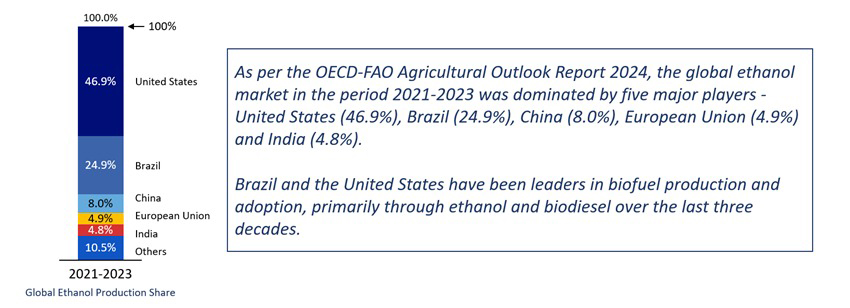

The U.S. is the world's largest ethanol producer, generating approximately 17.7 billion gallons of corn-based ethanol annually, which constitutes about 10% of the country's gasoline supply. Meanwhile, the European Union focuses on biodiesel sourced from rapeseed, soybeans, and waste oils.

Ethanol and its Production Technology

-

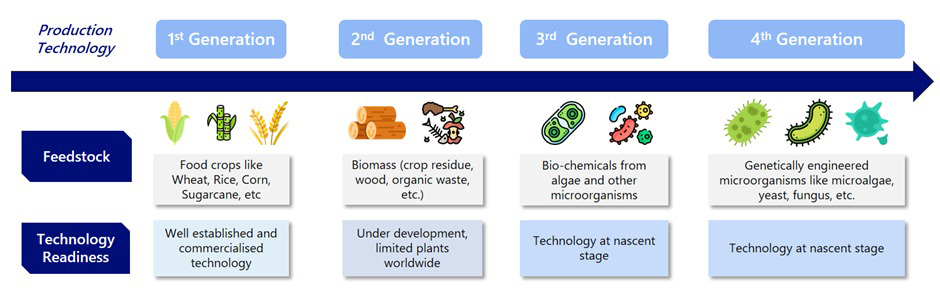

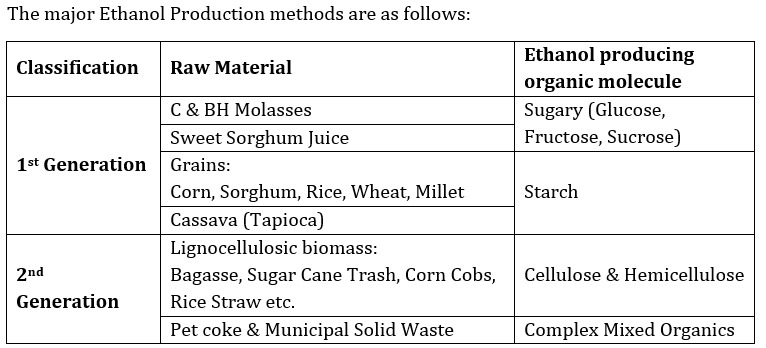

First-Generation Ethanol: Ethanol is produced via conventional processes through fermentation of sugars from crops like sugarcane, corn, and wheat, and used for direct blending in gasoline (petrol). There has been growing focus on production of ethanol from maize to shift demand for feedstock away from water intensive food crops like sugar and rice in India.

-

Second-Generation Biofuels: Ethanol is produced from non-food feedstock such as lignocellulosic biomass (corn hub, rice husk, wheat straw and sugarcane bagasse) and waste materials.

-

Third-Generation Ethanol: Ethanol is derived from algae and other microorganisms and can also involve the use of CO2 as feedstock.

-

Fourth-Generation Biofuels: This category involves capturing and storing CO2 to produce ethanol using genetically engineered microorganisms, including microalgae, yeast and fungus.

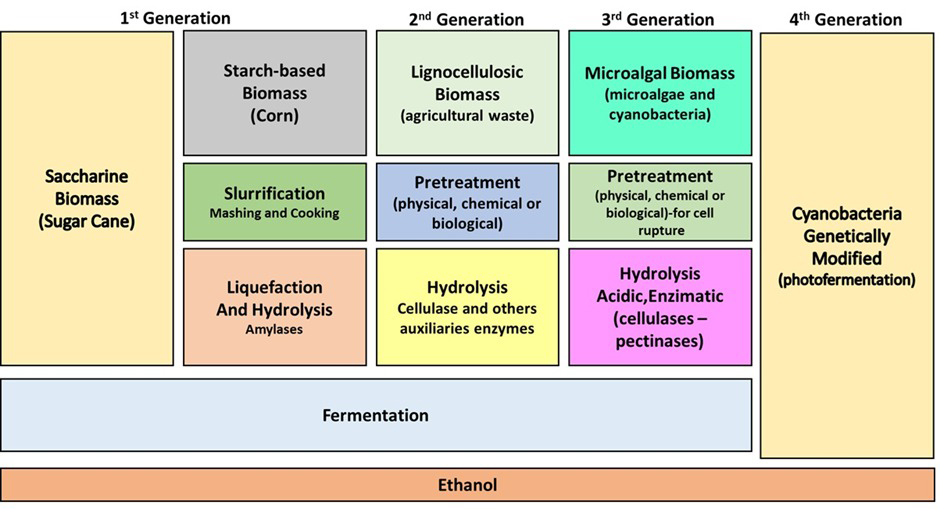

Different generations of ethanol offer distinct benefits and challenges and have a unique set of feedstock requirements. From a technical viability and commercialization perspective, first generation (1G) ethanol production is well-established and commercialized. Second generation (2G) ethanol production solutions are available in the market but require more complex and costly processing technologies, limiting overall commercialization. Third generation (3G) technology is in a nascent stage whereas fourth generation (4G) production is still at a concept stage and needs dedicated R&D efforts for further development. The production process of different generations of ethanol is shown in the figure below :

Figure: Different generations of ethanol

Ethanol Blending in Automotive Industry

Ethanol blending refers to mixing ethanol, derived from plant-based sources, with gasoline to create a cleaner-burning fuel, reducing reliance on fossil fuels and emissions. Among liquid biofuels, ethanol is the most widely used for blending with petrol.

Brazil produces around 7 billion gallons of ethanol annually. The country pioneered ethanol integration into the transportation sector in the 1970s, with the Proálcool plan (1975), an initiative aimed at reducing the country’s reliance on fossil fuels by blending gasoline with ethanol, investing in research and development, expanding sugarcane cultivation, and boosting ethanol plant capacities.

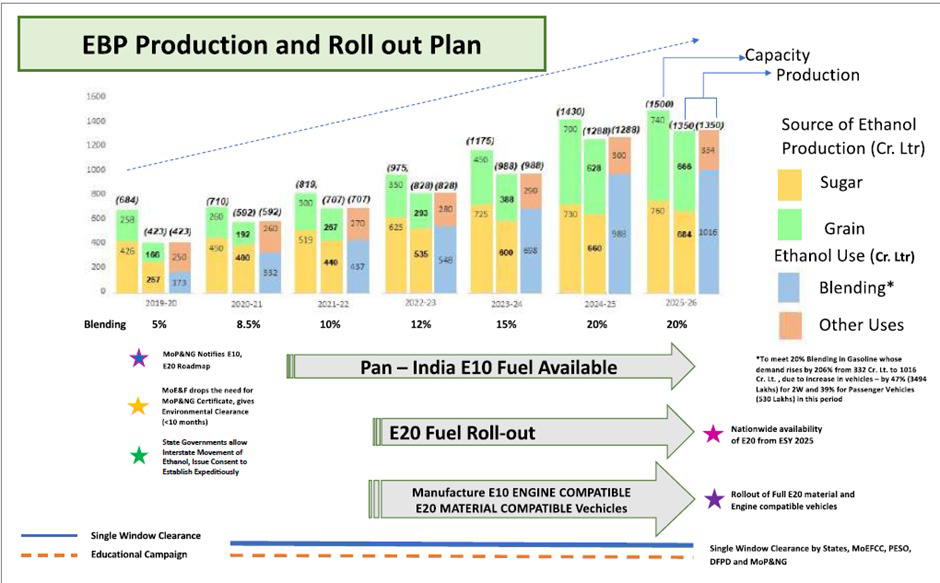

India began ethanol blending in petrol as a pilot project in 2001 to support the agriculture sector and reduce environmental pollution. The government supplied 5% ethanol-blended petrol to retail outlets and conducted R&D studies alongside field trials. The success of these trials led to the establishment of the Ethanol Blending Petrol (EBP) program in India . The government has advanced the target for 20% ethanol blending in petrol by 2025-26 from 2030.

Schematic pathways of first-, second-, third and fourth generation ethanol production

Source: Bioethanol from Microalgal Biomass: A Promising Approach in Biorefinery, Carlos Eduardo de Farias Silva1,2 https://orcid.org/0000-0002-1462-1145

Benefits of Ethanol Blending

Apart from emerging technologies such as electric vehicles, hydrogen, and fuel cell vehicles, biofuels (e.g. ethanol) present a viable solution for reducing carbon emissions. Derived from organic materials such as plants and agricultural waste, biofuels (e.g. ethanol) can significantly lower the carbon footprint due to their closed carbon loop. The CO2 absorbed during the growth of biofuel feedstock offsets the emissions released during fuel combustion, contributing to a reduction in air pollution, particularly arising from the transportation sector.

Furthermore, adopting ethanol can help in reducing crude oil import dependency, enhance energy security, and support rural economies in a country. It can be a critical step toward achieving climate goals, reducing greenhouse gas emissions, and fostering a sustainable environment.

Emission Reduction

Ethanol consists of higher hydrogen-to-carbon ratio vis-a-vis conventional petrol, leading to lower emissions. From March 2003 to 2022, ethanol consumption in Brazil (anhydrous and hydrous) saved 600 million tons of CO2eq being emitted into the atmosphere. By way of reference, it would require planting 4 billion native trees over the next 20 years to achieve the same CO2 savings.

Additionally, for the second-generation ethanol, the raw material used is the farm waste like corn cobs, rice husks, wheat straw and sugarcane bagasse that can all be transformed into cellulose and fermented into ethanol . This process takes away farm waste that is burned in the farm lands to prepare the soil for next sowing season.

Every year, the smoke produced from stubble burning by farmers in North India has been a major subject of concern due to the considerable health risks it poses . With the diversion of farm waste towards production of the biofuels like ethanol, emissions due to traditional practices like Parali burning can be curbed. The 2G ethanol plant at IOCL’s Panipat refinery, which is the country’s first such commercial project, which will directly manufacture 100 kilogrammes of ethanol per day from 425.5 metric tonnes of dry corn stover. According to its current capacity, this factory is expected to consume around 4,250 quintals of paddy straw from approximately 212 acres each day and empty approximately 77,562 acres each year, thus saving emissions .

Circular Nature of CO2 in Nature

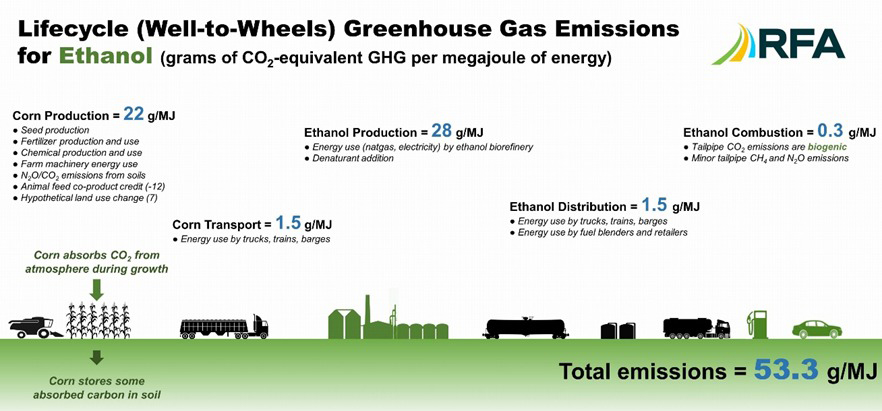

As per the IEA report titled “ Case studies of CO2 utilization in the production of ethanol”, Dec, 2024- Brazilian sugarcane ethanol and corn ethanol have global warming potential in the range of 20—25 gCO2e/MJ, which represents GHG savings of 70%—80% compared to regular gasoline.

This value is attained because of best management practices in crop production such as double cropping with soybeans which reduces nitrogen fertilizer demand in the case of corn and the use of biomass as fuel in the industrial process instead of fossil fuels. It was also noticed that ethanol production via sugar fermentation will lead to produce a high-purity CO2. This CO2 released during the fermentation of biomass corresponds to CO2 that was once sequestered from the atmosphere via photosynthesis by biomass crops, thus qualifying it as biogenic CO2 whose net effect on atmospheric concentrations can be considered zero (Figure below )

Figure: CO2 release during ethanol fermentation is carbon neutral.Source : IEA report titled “ Case studies of CO2 utilization in the production of ethanol”, Dec, 2024

Renewable Source of Fuel

Unlike the mining of coal, the production of petroleum and natural gas, renewables convert natural resources directly into fuel sources. Additionally, as sourcing fossil fuels is becoming harder and more expensive to procure for utilization at the cost of natural habitats and significant finances, renewable energy never runs out .

Fuel Security for the Nation

The use of ethanol in Brazil over the past two decades, has resulted in saving over 100 billion liters of fossil fuels from being consumed and imported, a cost savings estimated at USD 50 billion.

In the last ten years (2014-2024), EBP programme in India has translated into forex impact of over Rs.1,08,600/- crore, net CO2 reduction of 557 Lakh Metric Tonnes (LMT), a substitution of 181 lakh metric tons of crude oil and expeditious payment to farmers to a tune of over Rs. 92,400/- crores .

Sugar Manufacturers

In both 1st & 2nd generation production methods, sugar producers can provide raw materials required for ethanol production. Using already available raw materials, multiple sugar manufacturers have jumped on the ethanol production bandwagon. Additional revenue earned by sugar mills/distilleries through sale of ethanol to OMCs is expected to clear the sugar cane price arrears owed to farmers.

Farmers

The production of ethanol in the sugar distilleries and usage as a fuel will allow diversification and safer economic avenues for the households, dependent on farm incomes. Additionally, a conducive and sustainable ecosystem for 2G ethanol production method will allow usage of farm waste generated. This will once again boost income of farmers and prevent some traditional waste disposal practices that harm farm output and surrounding environment.

Diversification of Farm Economy

Figure: CO2 release during ethanol fermentation is carbon neutral.Source : IEA report titled “ Case studies of CO2 utilization in the production of ethanol”, Dec, 2024

Engine & Vehicle Compatibility

Since April 2023, all the vehicles sold in India are E20 fuel material complaint with the OEMs targeting to launch E20 engine compliant engines by April 2025.

Source: ROADMAP FOR ETHANOL BLENDING IN INDIA 2020-25, Niti Aayog , MoPNG , June 2021

Ethanol-based Flex-Fuel Technology

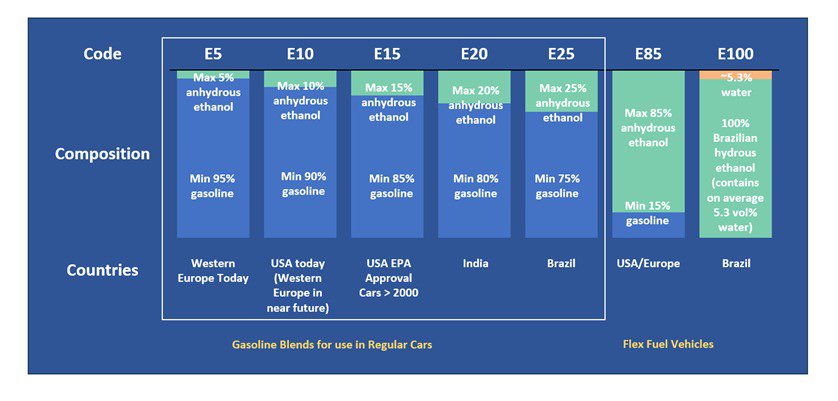

Flexible Fuel Vehicles (FFVs) are modified ICE vehicles capable of operating entirely on gasoline or any blend of gasoline and ethanol. E85 (or flex fuel) is a term that refers to high-level ethanol-gasoline blends containing 51% to 83% ethanol, depending on geography and season.

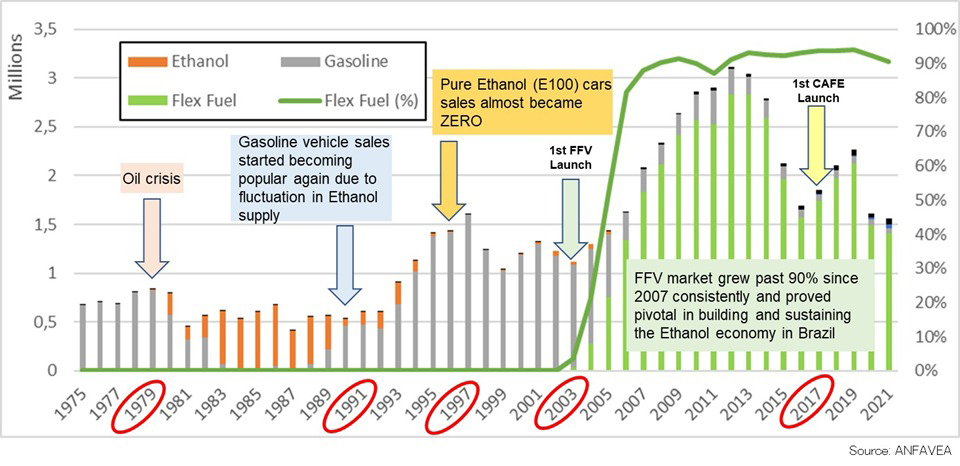

Brazil is a leader in adoption of FFVs with ~93% of the cars with a flex-fuel engine . Flex Fuel Vehicles (FFVs) have been present in the Brazilian automotive market since March 2003, when mass production and commercialization significantly increased in Brazil and accelerated the race to produce alternative fuels. In just over 17 years, this technology has come to dominate the Brazilian market. In recent years FFV have accounted for 98% of new cars sold nationally. Now, 80% of vehicles (30 million units) and 34% of motorcycles (5 million units) in Brazil are flex-fuel.

This major shift in vehicle production has brought numerous environmental and economic benefits to the country.

Ethanol Standards & Regulations

Brazil: Ethanol blends have been in use in Brazil since 1924, but it was only in the mid - 1970s that they became mandated. The 1970s oil crisis emphasized the need to reduce the country’s high dependence on oil imports. At the time 81% of Brazil’s oil came from abroad. In response, the government developed a public policy to incentivize the use of domestic ethanol as a fuel for the lightweight vehicle fleet. This included a combination of laws, regulations and financial incentives which brought about a national blending program. The blend percentage has varied until it stabilized in 2015 at 27% v/v ethanol blend for regular gasoline.

The composition of gasoline does not have to be changed to be blended with anhydrous ethanol. In fact, the ethanol blend eliminates the need for aromatic additives for octane improvements such as toluene and xylene.

The current Brazil specification is 27% v/v of anhydrous ethanol blended with gasoline. Anhydrous ethanol is a pure substance that has at least 99.6% v/v alcoholic strength. This change was introduced following extensive testing by trade associations representing cars, motorcycles and auto-part manufacturers to demonstrate technical and environmental feasibility. Industry consensus ensured all the actors along the value chain were heard and their concerns addressed in adopting the new blending standards.

Ethanol blending results in octane improvement, but occurs only if the fuel specification requires it. Otherwise, oil companies would be incentivized to use cheaper fractions to the blend which would keep the motor octane number/research octane number (MON/RON) at the same lower-performing level.

An octane rating (or octane number) is a standard measure of an engine’s gasoline capability against compression. The octane rating of gasoline is a measure of the fuel's tendency to burn in a controlled manner. This is important to know when choosing a fuel for a particular engine. The MON/RON are reached after running tests and observing how the engine behaves with a certain fuel. Improved octane levels heighten an engine’s performance and efficiency.

E10 blends are typically rated as being two to three octane numbers higher than regular gasoline. Modern engines, designed to take advantage of higher RON from E20 blends, can reach 3% consumption efficiency with drivability improvements.

Brazil started promoting ethanol blended gasoline in 1979 due to oil crisis. Automobile manufacturers were informed to develop and manufacture passenger vehicles running on Ethanol. Initially vehicles using ethanol were received well. However, due to ethanol supply fluctuations /concerns the program could not be sustained. Considering the performance, efficiency and other issues, customers also were not willing to buy pure ethanol (E100) vehicles. Sales started plummeting from the mid-80s to late 90s thereby adversely impacting ethanol usage. By 1995 pure ethanol vehicles sales became almost zero.

Seeing the variability and availability of ethanol due to which the customers were not ready to buy pure ethanol (E 100) vehicles, Brazilian Government ensured base Ethanol blend across the country to be E22 and promoted Flex Fuel Vehicles (which can use any ethanol blend between E22 and E93) developed by OEM in early 2000. With policy support from the Government, in terms of lower taxation on the FFVs and differential fuel price, sustained Ethanol supply ensured by policy interventions, FFV became popular in 2007. FFVs sales increased YoY and achieved market share of 90% thereafter. This led to an exponential increase in ethanol use by cars. The vehicle powertrain mix and the accompanying sharp rise in ethanol usage post 2003 due to large FFV adoption in Brazil over the past 50 years is given in Figure 1.

Driver of growth for FFV in Brazil: Considering the potential adverse impact of using higher ethanol blend in mono fuel vehicles which are developed for E22 and E27 fuel, Brazil did not increase base blend from E22 / E27 for many years. Additional ethanol produced was used to promote FFV vehicles keeping the base blend supply unaffected. This was also influenced by geographical & economic factors as there are many regions in Brazil that do not produce ethanol and the transportation of larger amounts of ethanol to these regions to meet higher blends would have increased its costs thereby adversely impacting customer acceptance in these regions. Currently with E27 as base blend 90 % of vehicles sold being FFVs, the average total ethanol blending in Brazil is around 45%. This is achieved over 3 decades with sustainable production, distribution, pricing model with policy interventions.

Hence the approach of using FFVs along with suitable Govt policy incentives (lower tax on FFVs and adequate pricing difference between E100 and Gasoline (E27) to promote greater ethanol usage) has been found to be more effective as compared to suddenly increasing the regulated ethanol blend percentage. This approach also prevents the need for having multiple protection fuels (E10, E20, etc.) for older in use vehicles and multiple engine modifications, their testing and homologation requirements for the OEM’s. FFV’s can accommodate any higher blends of Ethanol available in line with Government desired objectives.

As a result of the above approach, the benefits that have accrued to Brazil are summarized in Figure 1 as under.

FIGURE 1 – BENEFITS TO BRAZIL FROM USE OF ETHANOL AS FUEL.

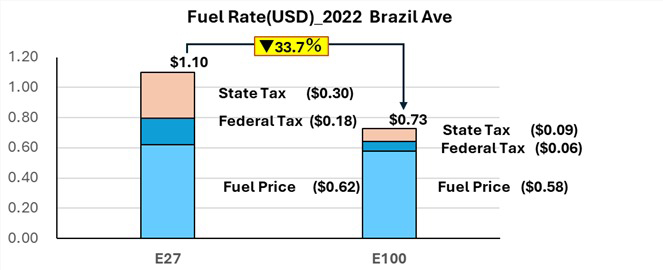

Brazil Govt policy support for promoting Ethanol consumption - Preferential tax rates for FFVs and E 100 Vs E 20 fuel

The Brazilian government has continuously supported the consumer adoption of FFVs to sustain ethanol economy by providing tax incentives to FFVs (around 15% advantage over gasoline vehicles) and by keeping gap in ethanol vs Gasoline fuel price of more than 30% through the control of federal and state taxes. The price difference in E27 Vs E100 in Brazil along with the Government taxation structure is given in Figure 2.

FIGURE 2– GOVERNMENT POLICY INTERVENTION FOR PRICING OF E 100 VS E 27 IN BRAZIL

CAFE regulations in Brazil and treatment of Ethanol as Carbon Zero Fuel:

In Brazil ethanol, being biogenic in origin, has always been considered as a zero-carbon fuel. This is in line with international norms e.g. norms set by International Panel on Climate Change (IPCC). When Brazil introduced first CAFE norms in 2017, FFV sales were already more than 90% with almost all vehicles manufactured in Brazil being FFVs. Hence, the policy priority of the Govt was to promote and encourage enhanced efficiency of FFVs. In CAFÉ 2 (from 2022) in addition to providing Biofuel credit as incentive to OEMs to improve FFVs efficiency using Ethanol compared with Gasoline (over and above and different from the traditional off cycle benefits), Brazil also introduced vehicle labelling program ethanol being zero carbon fuel. These Vehicle labels show the fuel efficiency of the vehicles as well as the carbon emissions, wherein carbon counting for the biofuel portion is considered zero.

CAFÉ-3: With the supportive Government policies, Brazil has already attained the overall average Ethanol blending of more than 45%. Now with carbon emissions becoming the focus area in the world through COP commitments, Brazil is now also considering carbon intensity of various fuels for reducing carbon footprints and has started issuing certificate for the carbon intensity of different fuels. This is being done scientifically and is being certified by the Government agency. The carbon emission from ethanol is taken as zero.

In Summary, Government and OEMs have worked together for energy security of Brazil. Brazilian government extended support through suitable policy incentives such as lower tax on FFVs, adequate sustained pricing differences between E100 and Gasoline (E27) to promote greater ethanol usage, Biofuel credits in their CAFÉ regulations as incentive to OEMs as well as strong customer awareness initiatives are the key steps taken in Brazil towards adoption of Ethanol in the country w.r.t capacity expansion and ethanol availability.

India: In January 2003, the Indian government launched the Ethanol Blending Petrol (EBP) Programme in 9 states and 4 Union Territories, offering 5% ethanol-blended petrol. After positive outcomes, the Ministry of Petroleum & Natural Gas expanded the program to 20 states and 4 Union Territories w.e.f 1st November, 2006. Public Sector Oil Marketing Companies (OMCs) were asked to sell 5% ethanol-blended petrol, subject to commercial viability as per Bureau of Indian Standards (BIS) specifications in the notified states and UTs . Similarly, Indian OEMs have also launched various flex fuel prototypes in the country. To support the adoption of these vehicles, the government of India launched E100 fuel at 183 stations in March 2024.

Some of the key Indian standards published and are alligned with the ethanol blended fuel are mentioned below

- Non-inclusion of conversion of grains to Ethanol, resulting in restriction of grain-based distilleries’ participation in the EBP Programme (Only Molasses based distilleries were part of the EBP Programme)

- High Taxation on Ethanol (18% tax rate was applicable)

- Procurement Challenges due to poor infrastructure and multiple tenders’ applications on a given Ethanol Supply Year (ESY)

- Dissatisfactory ‘take home’ price and irregular pricing for ethanol suppliers

- Limited feedstock (raw material) availability

- Constraints on the part of State Government Policies

However, the true potential of ethanol blending was never disputed. Since 2014, concerted interventions by the Indian Government have led to remarkable improvements. By June 2022, India achieved the 10% ethanol blending target, and advanced the 20% blending target to 2025-26 from 2030.

Blending of ethanol further increased to 12.06% in ESY 2022-23, 14.60% in ESY 2023-24 and reached to 20% as of June 2025. Source : Government measures to increase Ethanol Blending beyond 20% . Posted On: 20 MAR 2025 3:37PM by PIB Delhi

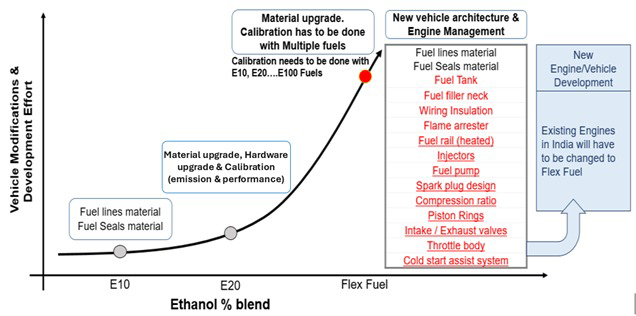

- The picture below shows the extent of change as blends of Ethanol is changed from E20 to E85.

- The addition of the above listed components will lead to substantial increase in the vehicle price for customers. 2W price will increase about 8% to 10% and for 4W also it will be a significant increase.

Blending & Distribution Infrastructure

Brazil: EBrazil has long held the position of being the largest producer of sugar in the world. In 2024-25, the country produced 43 million metric tons of sugar, accounting for 23% of the total global production. In Brazil pure gasoline is no longer sold, and a mandatory ethanol blend requirement of 27% is present. This has forced the adoption of flex fuel vehicles, cars that can switch between any gasoline-ethanol blend, from 100% gasoline to 100% ethanol.

India: Under Ethanol Blended Petrol (EBP) Programme in India, supply of ethanol has increased from 38 crore litres in Ethanol Supply Year (ESY) 2013-14 to 707.40 crore litres in ESY 2023-24, thereby achieving an average blending of 14.60% ethanol in Petrol. This remarkable progress underscores a significant increase in the overall ethanol blending percentage, rising from 1.53% in 2014 to 15% in 2024XVI and further following an increasing trend and nearing 20% blending as of June, 2025.

Challenges

To maintain the momentum of ethanol blending in India, there are certain challenges which must be addressed. These include securing a consistent supply of ethanol, expanding the availability of ethanol through enhanced storage capacity and transportation infrastructure nationwide, and ensuring vehicle compatibility with higher ethanol blends to boost customer acceptance.

Ensuring Ethanol Supply: As per Niti Aayog, approximately 1,016 crore litres of ethanol will be required to achieve the Target of 20% ethanol blending by 2025. The total demand for ethanol, including other uses, is estimated to be around 1,350 crore litres. To meet this requirement, an ethanol production capacity of about 1,700 crore litres must be established by 2025, assuming the plants operate at 80% efficiency.

As of January 2025, ethanol distillation capacity in India stood at 1,713 crore litre per annum.

Expanding Ethanol Availability: To achieve large scale adoption of ethanol blends in India, it is essential to establish a robust supply chain that facilitates the efficient distribution of ethanol across the country.

Currently, the ethanol production in India is highly dependent on food crops like sugarcane and rice which are water intensive crops and can lead to food security concerns in the nation. To mitigate this issue and maintain the ethanol blending rates in the country, Indian government is encouraging production of ethanol from maize and adoption of second-generation ethanol which utilises non-food feedstock such as lignocellulosic biomass (corn hub, rice husk, wheat straw and sugarcane bagasse) and waste materials.

Ensuring Vehicle Compatibility: As India transitions to E20 petrol fuel by 2025-26, all vehicles operating on Indian roads will need to be material compatible with E20. To make the vehicles compatible with E20 fuel, engine tuning and various engineering interventions in fuel systems, electrical systems, exhaust systems, and engine components are required. OEMs are working tirelessly in this direction to make their engines compatible to E20 fuel and have also developed and showcased E20/flex-fuel vehicles, ensuring that all new vehicles sold from April 2023 onward are E20 compliant. However, most existing vehicles, currently on the road are compatible only with E10, with only a small fraction optimized for this blend.

Developing upgraded components for the numerous vehicle variants and retrofitting them onto the existing fleet presents a significant challenge. Over and above the technology and development requirements, there is a need for key policy enablers for wider acceptance and quick adoption by customers. The key policy enablers are listed below :

- Reduced GST rate for FFVs : 18% for 2W & appropriate fiscal support for 4W

- Differential fuel pricing considering lower energy content (35% lower than E10): To ensure cost of operation remains same – (International practice)

- Biogenic factor i.e. CO2 accounting in CAFÉ regulations: Due consideration of GHG reduction benefit for FFVs

- Storage and dispensing infrastructure readiness at retail outlets: Clear and published E85 introduction location road map. To start with surplus States and thereafter to all Metros & Tier 1 & 2 cities

- Additional Enablers: Policy stability - Decision to continue ICE Vehicles should be ensured, such that OEMs can invest further in development and manufacturing and expansion of E20 vehicles and FFVs.

Additionally, educating customers about their vehicle's compatibility with different fuel grades is necessary to counter any misinformation and promote the adoption of higher ethanol blends in India.